Various Instruments for Temperature Measurement

Today, many instruments are used as temperature sensors in industry. The following are typical means of measurement.

Glass thermometer.

Principle: Expansion and shrinking of a liquid (usually mercury or coloured alcohol) in a glass envelope due to temperature changes. It is widely used, being autonomous and not expensive. The possible measurement range with a glass thermometer is from - 200 °C to + 600 °C with an optimal accuracy of 0.03 °C.

Problems (with respect to the nondestructive evaluation of material by thermography, TNDE): Point and contact measurement, high toxicity of mercury where still used.

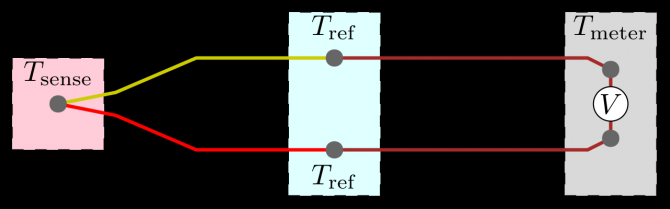

Thermocouple (invented by Seebeck in 1821).

Principle: An electric circuit formed of two different materials produces an electromotive force proportional to the temperature difference between the two junctions. Range: from near absolute zero up to 2750 °C.

Advantages: One of the cheapest measurement methods; versatile, since the probe can be inserted in various ways while the reading unit is remotely located.

Drawbacks: Electric signals produced are small and prone to noise (consequently it is difficult to obtain accuracy greater than 0.5 °C); one of the two junctions must be at a known temperature; sensitive to drifts; relatively fragile; point and contact measurement may perturb the thermal field being measured; relatively long time to stabilize and to obtain a reading (in the order of 1 s) even if the mass probe is small.

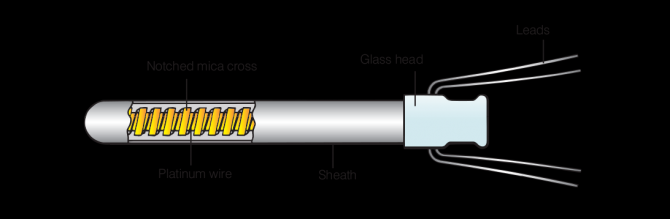

Resistance(method invented by Siemens in 1871).

Principle: The resistivity of a conductor follows temperature variations.

Advantages: reproducibility, excellent stability (for instance, platinum resistivity with a resolution of 0.006 °C is used as a temperature standard, Bailey 1988).

Drawbacks: point and contact measurement, fragile, expensive (if platinum is used), difficult to obtain a good thermal contact.

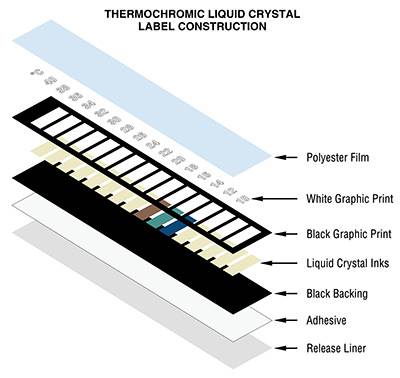

Liquid crystals.

Principle: Cholesterol esters change orientation with temperature and reflect coloured light from red to violet when illuminated with white light. Depending on their composition, a 0.01 °C resolution can be obtained.

Advantages: Not expensive; sensitive to slight thermal variations; surface measurement possible.

Problems: Contact measurement; restricted sensitivity range (e.g. 5, 10 °C); necessity to prepare the surface before application as paint (Crabol 1987) or encapsulated in small balls or film (Cohen 1973); cleaning necessary after measurement to remove the crystals.

Radiation measurements.

Principle: Remote measurement of emitted energy.

Advantages: Since there is no contact, no thermal equilibrium is necessary between the object and sensor.

Problems: Emissivity and spurious reflections; more costly than other temperature measurement techniques.

This last category of instruments represents a practical example of the simple idea of using heat flux to inspect the internal structure of materials. Commercial availability of radiation measuring devices in the mid 1960s allowed the use of TNDE to spread rapidly. Although some applications of TNDE are possible employing contact methods, their uses are limited (Williams et al. 1983).

Source: Nondestructive evaluation of materials by infrared thermography - Professor Xavier P.V. Maldague PhD.